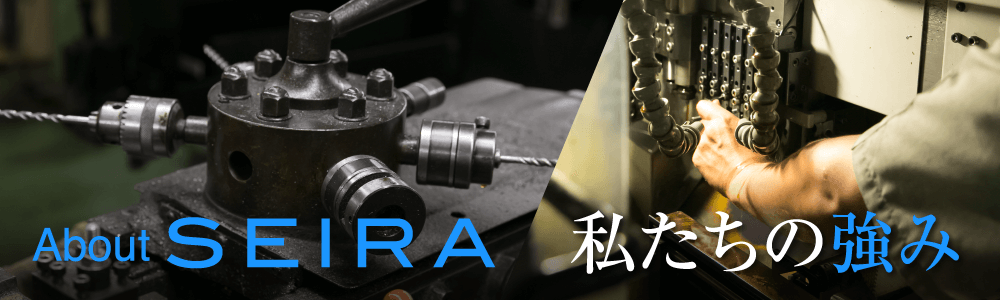

About Seira

Seira Co., Ltd. first started in 1948 as the Harasawa Screw Manufacturing, a screw product manufacturing plant in the Daimon neighborhood of Kazo City.

In 1996, we moved our plant to the Kazo Musashino Industrial Park, where products we manufacture include specialized bolts, nuts, and machine shafts.

To achieve μm-level machining precision, our plant is a temperature-controlled environment and we are machining products by CNC-controlled machines.

“Seira for Precision Screws” represents our pride as a manufacturer that combines skills and techniques passed down for generations with the latest machining technology. Our mission is to provide reliable craftsmanship.

machining diameter φ2mm~φ20mm length 600mm

Stainless steel, iron steel, nonferrous metals, etc.

Machining of precision parts and device components

■Registered as a Saitama Prefecture Certified Company for Business Innovation and Planning (April 26, 2012)

■Certified as a Sai no Kuni Plant (September 11, 2012)

Our four strengths

“Seira for Precision Screws” represents our pride as a manufacturer that combines skills and techniques, such as the complex machining techniques required for hydraulic components, cultivated over the years with the latest machining technology. Our mission is to provide reliable craftsmanship.

Our precision machining environment includes a temperature-controlled plant interior. Machining is conducted using automated CNC-controlled machines.

In production, we operate our plant with a small number of elite engineers. We work to achieve cost reductions by having every member be both engineer and programmer.

Sizes, special machining products or volume that cannot be completed in-house is processed at our partner companies. We utilize a network of precision screw machinists to provide high-precision products in a short delivery time.

Facility